Have you ever pondered the intricate processes that ensure the purity of the liquids we consume and the air we breathe? Beyond the visible filters, like the ones in your coffee machine or air conditioner, lies a world of invisible guardians – filter housings. These seemingly simple structures play a crucial role in maintaining the integrity of filtration systems, ensuring optimal performance and a steady flow of clean substances. And among the pioneers in this often-overlooked domain is Gelman Sciences, a company that has dedicated itself to crafting high-quality filter housings for over six decades.

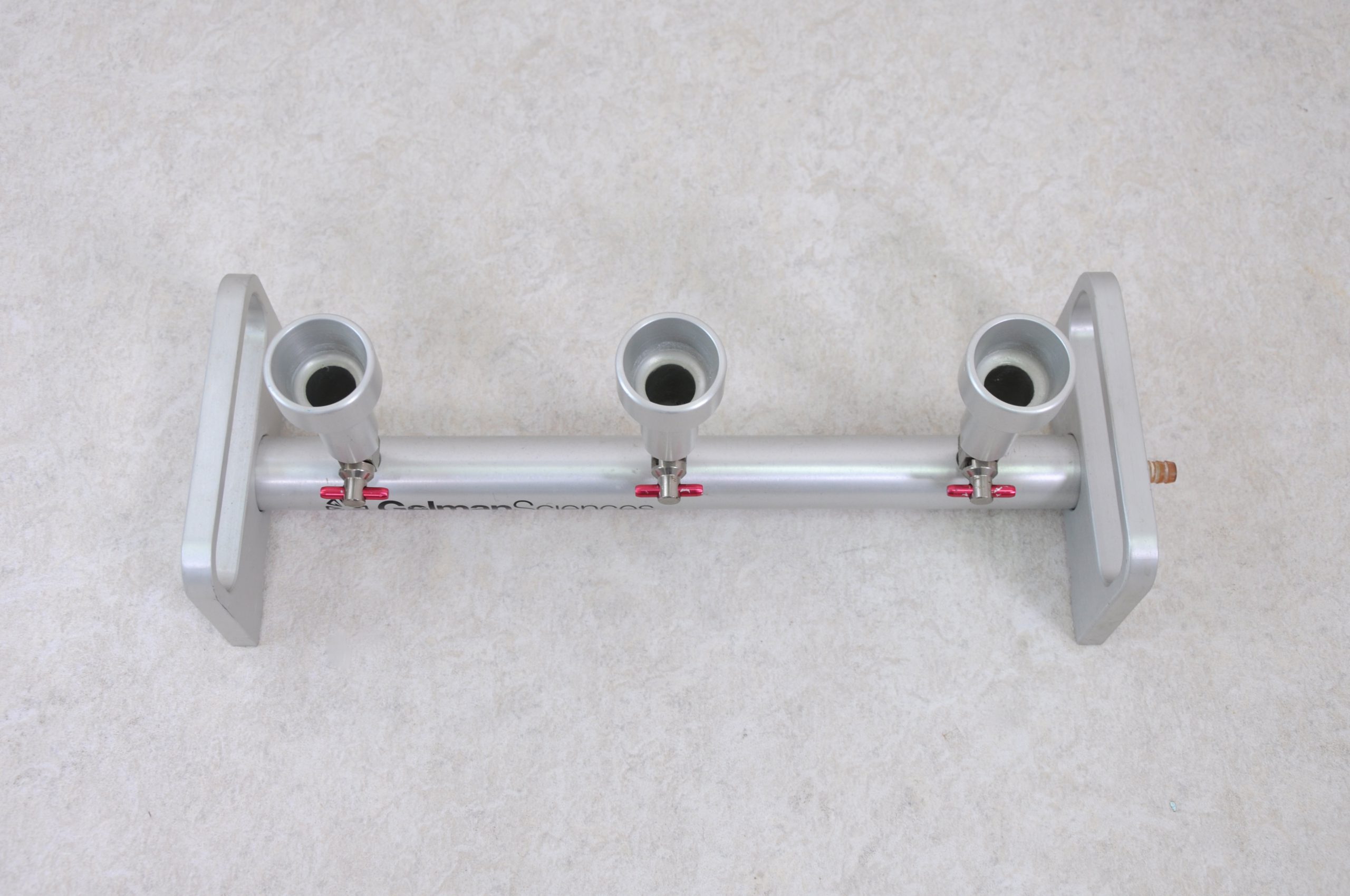

Image: www.tzsupplies.com

Gelman Sciences’ filter housings are vital components in various industries, from pharmaceutical manufacturing and biotechnology to food processing and water treatment. They provide a secure and reliable environment for filter cartridges, ensuring the effective retention of impurities and contaminants. But what makes these filter housings so special? And how do they contribute to the safety and efficiency of countless products and processes? Let’s delve into the world of Gelman Sciences’ filter housing, exploring the design, applications, and enduring legacy of this essential technology.

A Legacy of Innovation

Gelman Sciences’ journey began in 1959 with a vision to advance filtration technology. The company’s founding principle, “Making the World a Better Place,” has guided its innovation trajectory, culminating in the development of filter housings that set industry standards. Gelman Sciences has consistently prioritized quality, reliability, and customer satisfaction, establishing a reputation for producing robust and long-lasting filter housings.

Early Innovations

The company’s early success was rooted in its groundbreaking work with membrane filtration, a process that involves using semi-permeable membranes to separate different components of a fluid. Their innovative filter housings, designed to accommodate these membranes, revolutionized the filtration industry, offering a more efficient and precise way to remove contaminants.

Expanding Horizons

As industry needs evolved, so did Gelman Sciences. The company broadened its portfolio to include filter housings for a wide array of applications, encompassing:

- Sterilization: Gelman Sciences filter housings are vital in sterilizing fluids for pharmaceutical, medical, and biotechnology applications, ensuring the safety of vital products and processes.

- Particle Removal: From cleanroom environments to semiconductor manufacturing, Gelman Sciences filter housings play a key role in ensuring the precise removal of particles, preventing contamination and maintaining product integrity.

- Water Purification: The company’s filter housings power water treatment systems, removing impurities like sediment, chlorine, and bacteria, delivering clean and safe drinking water to homes and industries.

- Food Processing: Gelman Sciences filter housings are integral in ensuring the quality and safety of food products, effectively removing contaminants and extending shelf life.

Image: www.geminibv.com

The Science Behind Filter Housing

Gelman Sciences filter housings are more than just containers for filter cartridges. They are carefully engineered structures designed to optimize filtration performance and meet the specific requirements of diverse applications. Let’s explore the key elements that contribute to the effectiveness of these housings:

Materials: A Symphony of Strength and Compatibility

The choice of material is paramount for filter housing construction. Gelman Sciences employs a variety of materials, each selected for its unique properties and compatibility with specific applications. Common materials include:

- Stainless Steel: Known for its durability, corrosion resistance, and compatibility with a wide range of chemicals, stainless steel is a favored choice for filter housings in demanding environments.

- Polypropylene (PP): Lightweight, cost-effective, and chemically resistant, polypropylene is ideal for filter housings in food processing, pharmaceutical, and water treatment applications.

- Polyvinyl Chloride (PVC): Offering excellent chemical resistance and cost-effectiveness, PVC is frequently used for filter housings in industrial applications.

Design: Form Follows Function

The design of Gelman Sciences filter housings is a testament to the company’s commitment to optimizing filtration processes. Features like:

- Integrated Sealing Surfaces: Precision-engineered sealing surfaces ensure a tight fit for filter cartridges, preventing leaks and maintaining the integrity of the filtration process.

- Streamlined Flow Paths: Optimized flow paths minimize pressure drop, ensuring efficient filtration performance and reducing energy consumption.

- Easy-to-Access Components: Careful design allows for easy filter cartridge replacement and maintenance, simplifying operations and minimizing downtime.

Customization: Tailoring Solutions

Gelman Sciences recognizes that each application has unique requirements. Therefore, the company offers a wide range of customization options for its filter housings, including:

- Size: Filter housings are available in various sizes, accommodating varying needs and flow rates.

- Pressure Rating: Filter housings are engineered to withstand specific pressure ranges, ensuring safety and reliability in different applications.

- Connection Types: A variety of connection types, including threaded, flanged, and welded, are available to ensure compatibility with existing systems.

Applications: From Medicine to Food

Gelman Sciences filter housings are found in numerous industries, where they play a vital role in achieving clean, safe, and efficient processes. Let’s explore some of the key applications of these versatile components:

Pharmaceutical Manufacturing: Safeguarding Life

In the pharmaceutical industry, where the purity and sterility of products are paramount, Gelman Sciences filter housings are essential. They ensure the effective removal of contaminants from drug solutions, injectable medications, and other pharmaceutical products, safeguarding patient health.

Biotechnology: Advancing Innovation

Biotechnology relies heavily on filtration processes for cell culture media, reagents, and other critical solutions. Gelman Sciences filter housings provide the necessary protection for delicate biological materials, enabling breakthroughs in vaccine development, gene therapy, and other areas.

Food Processing: Ensuring Quality

In the food industry, Gelman Sciences filter housings play a crucial role in maintaining food safety and quality. They are used to filter liquids like juice, wine, and beer, removing unwanted particles and microorganisms, ensuring a clean and appealing final product.

Water Treatment: Bringing Clean Water to Communities

Gelman Sciences filter housings are at the heart of modern water treatment systems, enabling the removal of impurities, sediments, bacteria, and other contaminants from drinking water, ensuring safe and potable water for communities globally.

Industrial Processes: Supporting Efficiency and Safety

In various industrial processes, Gelman Sciences filter housings are vital for maintaining equipment lifespan and ensuring product quality. They filter lubricants, hydraulic fluids, and other industrial fluids, removing contaminants that can cause malfunctions and costly breakdowns.

The Future of Gelman Sciences Filter Housing

As technology advancements continue, the demand for more efficient, reliable, and sustainable filtration solutions is growing. Gelman Sciences remains at the forefront of this evolution, constantly exploring new materials, designs, and manufacturing techniques to adapt to evolving needs. Some of the key trends shaping the future of filter housing include:

- Sustainable Materials: The industry is moving towards sustainable materials, like recycled plastics and bio-based resins, to reduce environmental impact.

- Smart Technology: Incorporating sensors and data analytics into filter housings to monitor performance, predict maintenance requirements, and optimize filtration processes is a growing trend.

- Miniaturization: There is a growing demand for smaller and more compact filter housings, particularly for applications in portable devices and microfluidic systems.

The Enduring Legacy

Gelman Sciences’ filter housings have had a profound impact on various industries, contributing to the safety, quality, and efficiency of countless products and processes. Their legacy is built on a foundation of relentless innovation, unwavering commitment to quality, and a deep understanding of the ever-evolving needs of their customers. As the filtration industry continues to evolve, Gelman Sciences will undoubtedly remain a driving force, shaping the future of this vital technology for generations to come.

Gelman Sciences Filter Housing

From the Lab to the World: A Legacy of Trust

The story of Gelman Sciences filter housing is not just about innovation and technology; it’s about the positive impact these components have made on the world around us. They have played an essential role in ensuring the purity of life-saving medications, the cleanliness of our drinking water, and the safety and quality of the food we consume.

As you enjoy a glass of pure water, sip on a perfectly brewed cup of coffee, or use a product that resulted from cutting-edge scientific research, remember the unsung heroes working behind the scenes – the Gelman Sciences filter housings, silently guarding our health and well-being.

This article has provided a glimpse into the world of Gelman Sciences filter housing, highlighting their importance, design, applications, and future potential. The next time you encounter a filtration system, take a moment to appreciate the inconspicuous yet vital role these components play in our daily lives.

:max_bytes(150000):strip_icc()/OrangeGloEverydayHardwoodFloorCleaner22oz-5a95a4dd04d1cf0037cbd59c.jpeg?w=740&resize=740,414&ssl=1)