Imagine a time before digital scales, when weighing objects involved a delicate dance of sliding weights and careful adjustments. This was the world of the triple beam balance, a simple yet ingenious tool that has been used for centuries to measure mass with remarkable accuracy. From the bustling laboratories of scientists to the bustling markets of merchants, the triple beam scale has played a pivotal role in shaping our understanding of the world around us.

Image:

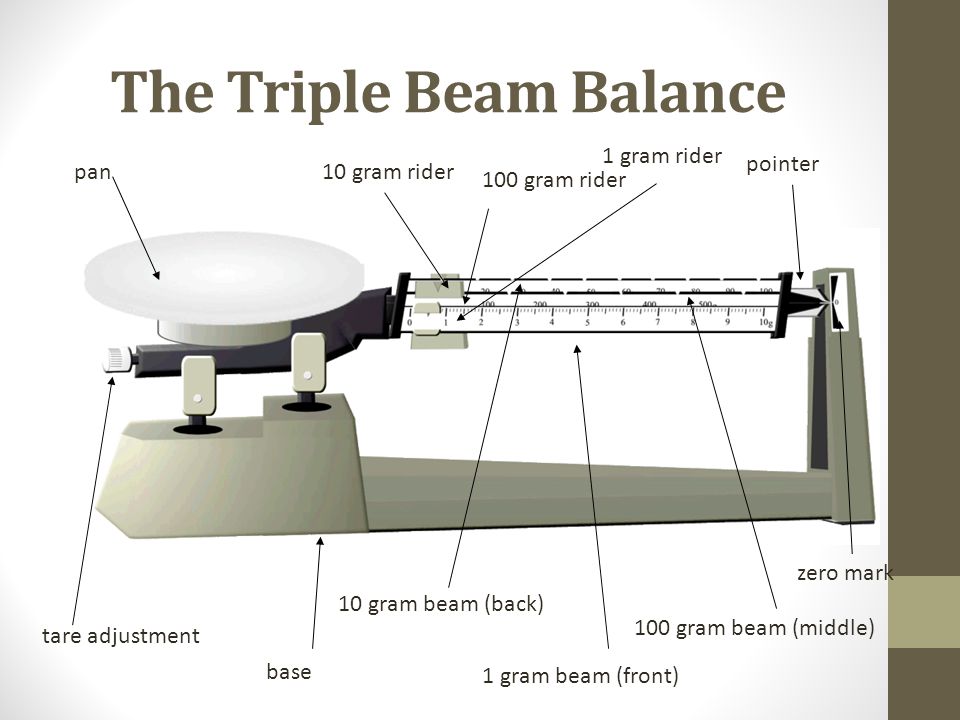

The triple beam balance, often called a triple beam scale, is a mechanical device that utilizes the principle of moments to determine the mass of an object. It consists of a beam with three sliding weights, each calibrated to a specific range of values. By adjusting the positions of these weights, we can precisely balance the beam against the weight of the object being measured, allowing us to read the mass directly from the scale.

History of the Triple Beam Scale

From Ancient Origins to Modern Innovations

The origins of the triple beam scale can be traced back to ancient civilizations, where the concept of balancing weights was used to measure precious metals and other commodities. Early balances were rudimentary, often consisting of a simple beam suspended from a central point. Over time, these balances evolved into more sophisticated instruments, with advancements in materials and design. The invention of the triple beam scale, however, is credited to the late 19th century, a time marked by industrial innovation and technological progress.

The earliest triple beam scales were primarily used in scientific laboratories, where precision measurements were paramount. Scientists relied on these scales to accurately weigh chemicals, materials, and samples during their experiments. As technology advanced, triple beam scales became increasingly sophisticated, incorporating features like damping mechanisms to reduce oscillations and improved calibration for greater accuracy. By the early 20th century, triple beam scales had transitioned beyond the confines of the laboratory and began finding applications in various industries, including education, agriculture, and manufacturing.

The Mechanics of a Triple Beam Scale

Image:

A Simple Yet Powerful System

At its core, the triple beam scale operates on the principle of moments, which states that the moment of a force (the product of its magnitude and perpendicular distance from a pivot point) is equal to the moment of the opposing force. In the case of the triple beam scale, the object being weighed creates a moment that balances against the moment created by the sliding weights.

The beam of the scale is a rigid bar supported at its center by a pivot point, known as the fulcrum. On one side of the fulcrum rests the object being weighed, while on the other side are three sliding weights, each representing a specific range of mass. The weights can be moved along the beam, altering their distance from the fulcrum and thus the moment they create.

To operate a triple beam scale, the object is placed on the platform, causing the beam to tilt downwards. The operator then adjusts the position of the weights until the beam returns to its equilibrium position, where it balances perfectly. The sum of the readings on the weight scales indicates the mass of the object. This process is repeated for each weight beam, starting with the beam with the largest values and moving down to the beam with the smallest values. The triple beam scale is so named because of its three beams, each calibrated to a specific weight range (usually grams, kilograms, or pounds) to measure the mass of objects up to a specific limit.

Applications of the Triple Beam Scale

From Science Classrooms to Research Laboratories

The triple beam scale is a versatile instrument with a wide range of applications. Here are a few examples:

- Education: Triple beam scales are commonly used in science classrooms across all levels to introduce students to the concepts of mass, weight, and measurement. They offer a hands-on experience that allows students to explore these principles through direct experimentation.

- Scientific Research: Triple beam scales are still used in many research laboratories, particularly in chemistry, physics, and biology, for precise weighing of chemicals, materials, and samples. While digital balances have become more prevalent, the triple beam scale remains a reliable and economical option for many research applications.

- Agriculture: Triple beam scales are used in agricultural settings to measure the weight of produce, feed, and other materials. Farmers rely on these scales to determine the yield of their crops, manage inventory, and ensure accurate pricing.

- Manufacturing: Triple beam scales are essential tools in manufacturing environments, where precise weighing is critical for quality control and production efficiency. They are used to measure the weight of ingredients, components, and finished products, ensuring that each item meets the required specifications.

- Other Applications: Triple beam scales find use in a wide range of other industries, including healthcare, jewelry making, and even in hobbyist pursuits like model building and baking.

Advantages and Disadvantages of the Triple Beam Scale

Weighing the Pros and Cons

Like any tool, the triple beam scale has its own set of advantages and disadvantages. Here’s a breakdown:

Advantages:

- Accuracy: Triple beam scales are known for their high level of accuracy, typically achieving precision within a few hundredths of a gram.

- Reliability: Mechanical scales like the triple beam are built to last and are less prone to damage or failure compared to electronic scales.

- Simplicity: Operating a triple beam scale is relatively straightforward, requiring no complex electronics or programming. This ease of use makes them suitable for both beginners and experienced users.

- Cost-effectiveness: Triple beam scales are generally more affordable than digital scales, making them a practical option for students, hobbyists, and smaller businesses.

Disadvantages:

- Limited Range: Triple beam scales have a limited capacity, typically ranging from a few hundred grams to a few kilograms. For heavier loads, a different type of scale is required.

- Slower Operation: Adjusting the sliding weights on a triple beam scale can be a slower process compared to reading a digital display.

- Susceptibility to Environmental Factors: The accuracy of a triple beam scale can be affected by factors such as temperature fluctuations, vibrations, and drafts.

The Future of the Triple Beam Scale

Adapting to a Changing World

While the advent of digital scales has revolutionized weighing technology, the triple beam scale remains relevant and continues to find new applications. As a testament to its enduring legacy, the triple beam scale has been incorporated into digital weighing systems, enhancing the accuracy and reliability of these modern instruments.

The future of the triple beam scale lies in its ability to adapt to new technological advancements. The incorporation of digital interfaces, remote control functionalities, and integration with other devices opens up exciting possibilities for the use of the triple beam scale in diverse applications. From automated weighing systems in industrial settings to personalized health monitoring devices, the triple beam scale continues to be a vital tool for measuring the world around us.

Triple Beam Scale

Conclusion

From its humble beginnings in ancient civilizations to its continued relevance in modern society, the triple beam scale has become a symbol of precision and reliability. Whether used in a science classroom to introduce students to fundamental concepts or in a research laboratory to conduct cutting-edge experiments, the triple beam scale remains a powerful and versatile tool for measuring mass with incredible accuracy. It is a reminder of the ingenuity and simplicity that can be found in even the most basic tools, shaping our understanding of the world around us.

:max_bytes(150000):strip_icc()/OrangeGloEverydayHardwoodFloorCleaner22oz-5a95a4dd04d1cf0037cbd59c.jpeg?w=740&resize=740,414&ssl=1)