The warmth of radiant heating combined with the timeless beauty of wood flooring—it’s a match made in home design heaven. But not all engineered wood flooring is created equal when it comes to withstanding the unique demands of radiant heat. Choosing the right flooring can make all the difference in ensuring your floors look their best and last for years to come.

Image: cypresshomes.co

My own experience with radiant heat and engineered wood flooring solidified my understanding of this important factor. Our old house was a drafty mess, and radiant heat seemed like the perfect solution to upgrade our comfort level. I was excited to put in beautiful wood floors, but quickly learned that selecting the wrong type could mean warping, cracking, and a whole lot of frustration. So, I dove into research and consulted experts, and what I learned changed my approach to flooring installation. This article will share the wisdom I gained to help you make the best decision for your home.

Understanding Engineered Wood Flooring and Radiant Heat

Engineered wood flooring consists of multiple layers of wood veneer bonded together with a plywood or high-density fiberboard core. The top layer is made of a hardwood veneer, which gives the flooring its aesthetic appeal and durability. Engineered wood is a popular choice for both its affordability and stability, as it is less prone to warping and expansion than solid wood flooring.

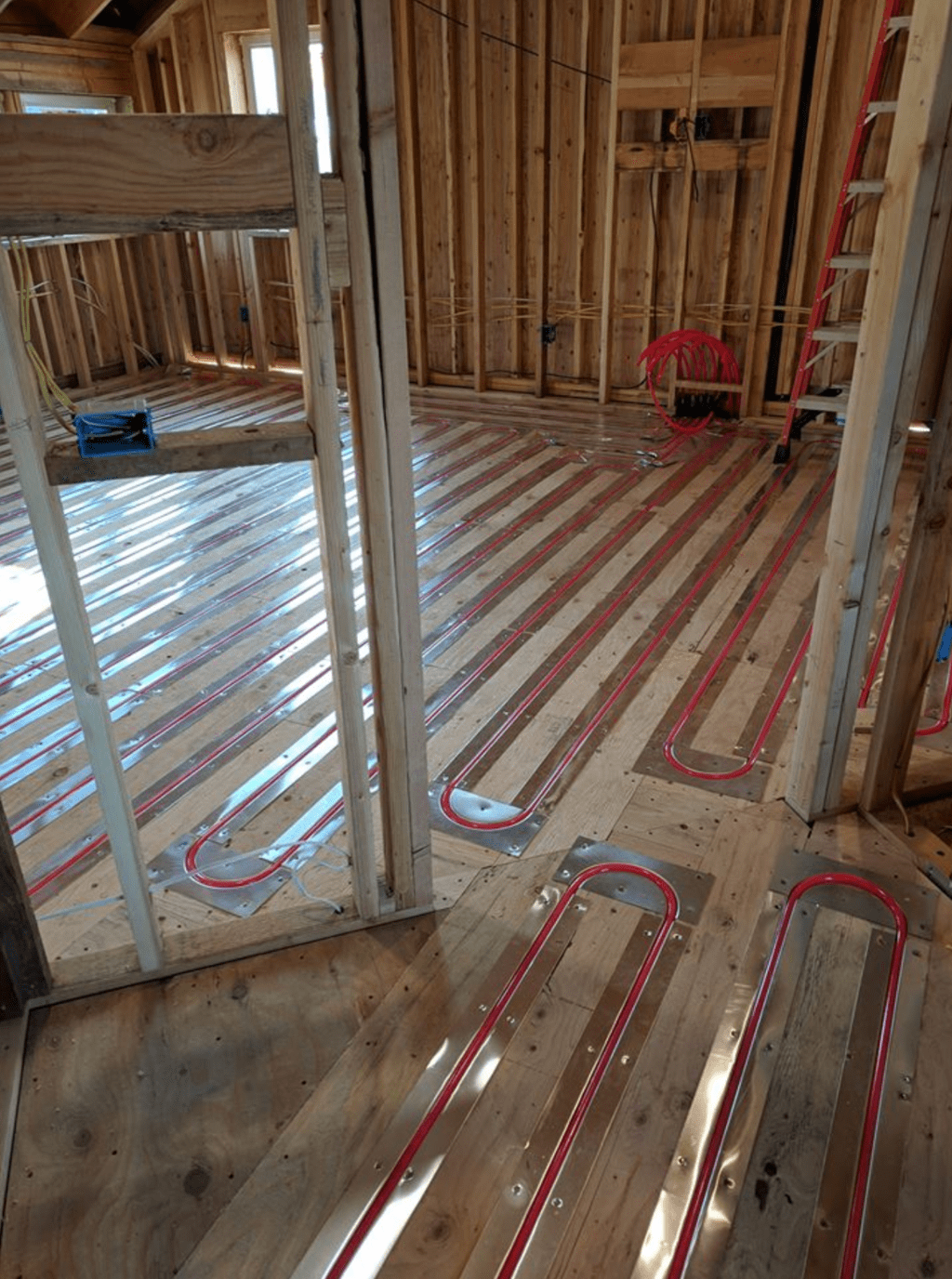

Radiant floor heating systems work by emitting heat from beneath the floor surface. This heat can be generated either through electric wires or hot water pipes embedded within the concrete slab or subfloor. Radiant heat offers a unique level of comfort and energy efficiency, warming homes evenly and reducing reliance on traditional heating systems.

Finding the Best Engineered Wood Flooring for Radiant Heat: Key Factors

1. Wood Species and Thickness

Hardwoods with denser wood, such as oak, maple, and hickory, tend to be more stable and better equipped to handle the fluctuations in temperature associated with radiant heat. These species are less likely to warp or crack.

A thicker top layer of veneer (3mm or greater) provides greater stability and durability, making this engineered wood flooring a better option for radiant heat applications.

Image: viewfloor.co

2. Wood Flooring Construction: Engineered vs. Solid

Engineered wood flooring is generally a better choice for radiant heat than solid hardwood. Here’s why:

- Stability: The multiple layers of engineered wood flooring help it maintain its shape and resist warping under varying temperatures.

- Installation: Engineered wood flooring can be glued down or floated over a subfloor, making it more compatible with radiant heat systems.

- Cost: Engineered wood flooring is often less expensive than solid hardwood, which can be a significant factor in any home renovation.

3. Moisture Content

Wood floors require a specific moisture content to maintain stability and avoid warping. For radiant heat, it’s crucial to know the recommended moisture content for the chosen wood species and ensure that your subfloor and ambient humidity levels are appropriate. Consult a flooring professional for specific guidance on this crucial factor.

4. Choosing the Right Finish: Oil vs. Polyurethane

The finish on your engineered wood flooring can also have a significant impact on its performance with radiant heat. Oil-based finishes are generally less resistant to heat and might require more frequent refinishing when exposed to radiant heat. Polyurethane finishes offer better durability and heat resistance, making them a preferred choice for rooms with radiant heating systems.

5. Flooring Manufacturer Recommendations

The best source of information on the compatibility of engineered wood flooring with radiant heat is the manufacturer. They will have specific guidelines and recommendations based on their flooring products and construction.

6. Expert Installation is Key

Even the best engineered wood flooring won’t perform as expected if it’s not installed correctly. Expert installers will understand the specific requirements for radiant heat applications and have the skills to ensure a smooth and stable installation.

Tips and Expert Advice

- Acclimate the wood planks before installation: Store the flooring in the room where it will be installed for at least 48 hours to allow the wood to adjust to the temperature and humidity. This helps to prevent warping and cracking.

- Choose a flooring adhesive designed for radiant heat: Ensure the adhesive is heat-resistant and compatible with engineered wood flooring.

- Allow for adequate expansion and contraction: Leave sufficient gaps around the perimeter of the flooring for expansion and contraction due to temperature changes.

- Use high-quality underlayment: Underlayment helps to dampen sound, insulate, and provide a smoother, more even surface for the flooring. Ensure your underlayment is compatible with radiant heat systems.

- Invest in a humidifier: Keeping the humidity levels in your home within a recommended range can help prevent excessive drying of the wood and reduce the risk of warping and cracking.

- Maintain the flooring: Follow the manufacturer’s instructions regarding cleaning, sanding, and refinishing. Regularly cleaning and maintaining your wood floors will help them last longer and look their best.

FAQs about Engineered Wood Flooring and Radiant Heat

Q. Is engineered wood flooring always better for radiant heat?

A: It’s generally recommended for its stability and compatibility. However, it’s crucial to ensure it’s engineered for radiant heat applications and complies with the manufacturer’s guidelines.

Q: Can any type of engineered wood flooring work with radiant heating?

A: No. Not all engineered wood flooring is suitable for radiant heat. It’s crucial to choose flooring specifically designed for this application. Consult the manufacturer’s recommendations and an expert installer for guidance.

Q: What are the benefits of engineered wood flooring over solid wood with radiant heat?

A. Engineered wood is typically more stable than solid wood, making it less prone to warping and expansion under fluctuating temperatures.

Q: How do I know if certain engineered wood flooring is radiant-heat ready?

A: The manufacturer’s specifications should clearly indicate the flooring’s compatibility with radiant heat systems. Consult with the manufacturer and flooring specialists for guidance.

Q: Do I need to use a special type of adhesive for engineered wood flooring with radiant heat?

A: Yes. Choose a heat-resistant adhesive explicitly designed for engineered wood flooring and compatible with radiant heat systems. Ensure it’s compatible with your flooring type and installation method.

Best Engineered Wood Flooring For Radiant Heat

Conclusion: Making an Informed Decision

Choosing the best engineered wood flooring for radiant heat involves careful consideration and research. By understanding the key factors discussed above, you can ensure that your floors look beautiful, perform well, and last for years to come. And remember, investing in expert advice from a flooring professional and adhering to the manufacturer’s recommendations is crucial for success.

Are you ready to begin your journey to find the perfect engineered wood flooring for radiant heat in your home? Let me know in the comments below if you have any specific questions or a unique situation you’d like to explore further.

:max_bytes(150000):strip_icc()/OrangeGloEverydayHardwoodFloorCleaner22oz-5a95a4dd04d1cf0037cbd59c.jpeg?w=740&resize=740,414&ssl=1)