Have you ever found yourself stranded with a flat tire, only to discover your trusty hydraulic floor jack is no longer lifting like it used to? The frustration of a malfunctioning jack can be a real pain, literally! This is where 3 ton hydraulic floor jack repair kits come in. These kits contain the parts and tools necessary to get your jack back in working order, saving you time and money in the long run.

Image: www.blackhawkparts.com

A 3 ton hydraulic floor jack is an essential tool for any car owner, mechanic, or DIY enthusiast. In the world of automotive repair, a jack’s reliability is paramount, and understanding the intricacies of floor jack repair is crucial for ensuring your repairs go smoothly and safely. This article will deep dive into the world of 3 ton hydraulic floor jack repair kits, providing a comprehensive guide to help you troubleshoot common issues and revitalize the lifting power of your jack.

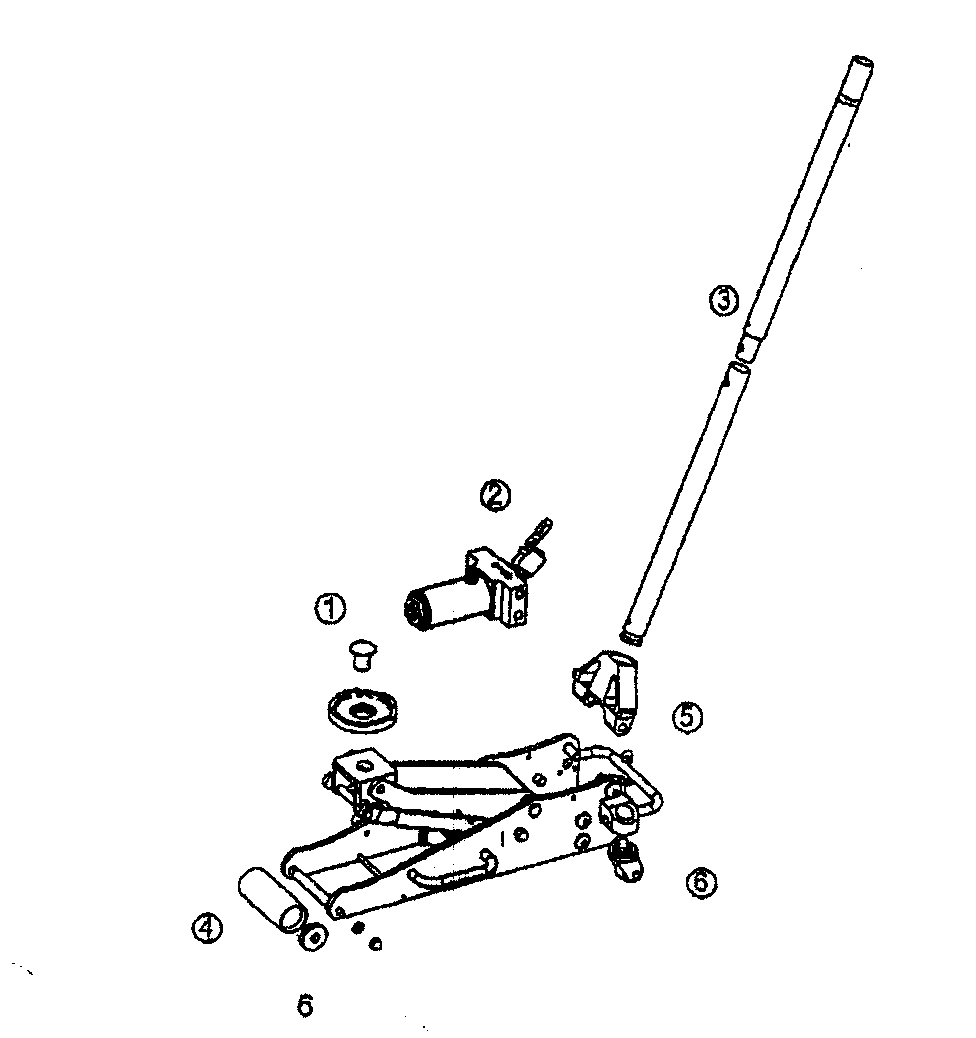

Understanding the Mechanics: Inside a 3 Ton Hydraulic Floor Jack

Before we dive into the repair process, let’s understand the components that make up a 3 ton hydraulic floor jack. These jacks are typically composed of the following:

- Base: The sturdy base provides the foundation for the jack.

- Pump: This is the heart of the jack, allowing you to build hydraulic pressure.

- Hydraulic Cylinder: This cylinder houses the piston that moves the lift arm.

- Lift Arm: The arm connected to the piston, responsible for raising the vehicle.

- Saddle: The platform that contacts the vehicle’s lifting point.

- Release Valve: Controls the release of hydraulic pressure, allowing the jack to lower.

- Safety Lever: Prevents accidental release of the lift arm.

Decoding the Common Culprits: Issues with Hydraulic Jacks

While hydraulic floor jacks are designed for durability, over time, they can succumb to wear and tear. Several factors can hinder the functionality of your 3 ton hydraulic floor jack, including:

- Fluid Leakage:Hydraulic fluid leaks around seals or the cylinder itself can result in sluggish lifting performance.

- Clogged Pump: Dirt and debris can accumulate in the pump, making it difficult to build pressure.

- Worn Seals: Hydraulic seals, over time, can become brittle and ineffective, causing leaks.

- Damaged Piston: If the piston becomes scratched or damaged, it can hinder proper movement within the cylinder.

- Release Valve Issues: A malfunctioning release valve can lead to difficulties lowering the lift arm.

- Bent or Damaged Lift Arm: This can occur if the jack is overloaded or subjected to improper use.

The Rescue Squad: 3 Ton Hydraulic Floor Jack Repair Kits

Thankfully, you don’t have to throw away your trusty 3 ton hydraulic floor jack just because it’s showing signs of wear. Repair kits offer a comprehensive solution for restoring your jack’s lifting power. These kits typically include:

- Hydraulic Fluid: Essential for maintaining the hydraulic system.

- O-Rings and Seals: Replace worn or damaged seals to prevent leaks.

- Pump Repair Parts: Address issues with the pump, such as clogged valves or worn components.

- Release Valve Components: Repair a malfunctioning release valve.

- Optional Tools: For specialized repairs, some kits may include tools like wrenches and screwdrivers.

Image: carpet.vidalondon.net

Getting Your Hands Dirty: A Step-by-Step Guide to Repairing Your 3 Ton Hydraulic Floor Jack

Repairing a 3 ton hydraulic floor jack is not as daunting as it might seem. With the right kit and some basic mechanical skills, you can breathe new life into your jack. Here’s a general guide:

Step 1: Safety First

Always make sure the jack is fully lowered and the vehicle is properly supported before beginning any repairs. Wear safety glasses and gloves to protect yourself from potential hazards.

Step 2: Identifying the Problem

Inspect the jack for any signs of fluid leaks, damage, or wear and tear. Note the specific components that appear faulty. This will help you determine the necessary repairs.

Step 3: Preparing for the Repair

Follow the instructions included with your repair kit. Often, you will need to clean the jack’s components with a suitable cleaner before beginning the repair. This helps prevent contamination and ensures the new seals are properly installed.

Step 4: Replacing Seals and O-Rings

Carefully remove the old seals and O-rings. Refer to the kit’s instructions and diagrams for proper placement and orientation of the new seals. Make sure the new seals are properly lubricated with the appropriate hydraulic fluid.

Step 5: Addressing Pump Issues

If the pump is clogged, disassemble it according to the instructions. Clean the pump thoroughly, removing any dirt or debris. Replace any worn components for optimal performance.

Step 6: Repairing the Release Valve

If the release valve is malfunctioning, follow the instructions to replace any worn components. The kit should provide specific instructions for the release valve model you are using.

Step 7: Reassembly and Testing

Once the repairs are complete, reassemble the jack, ensuring all components are properly seated. After reassembly, test the jack to ensure it lifts and lowers smoothly.

Step 8: Fluid Level and Maintenance

After a successful repair, check the hydraulic fluid level and top it off as needed. It’s good practice to inspect your 3 ton hydraulic floor jack regularly for any signs of wear or fluid leaks. Preventive maintenance can help extend the life of your jack.

Beyond the Basics: Advanced Tips for Optimum Performance

While repair kits provide essential components, you can enhance your repairs and the longevity of your jack with these additional tips:

- Proper Storage: Store your jack in a clean, dry, and dust-free environment.

- Fluid Replacement: Consider regularly changing your hydraulic fluid., even if there are no leaks. This keeps the fluid clean and prevents wear and tear on the internal components.

- Lubrication: Lubricating moving parts, like the lift arm and the saddle, can reduce friction and wear.

- Thorough Cleaning: Before and after repairs, thoroughly clean your jack, using a suitable cleaner and a soft brush.

3 Ton Hydraulic Floor Jack Repair Kits

Conclusion: Empowering Your Lifting Needs

Using a 3 ton hydraulic floor jack repair kit allows you to tackle repair needs head-on. Knowing how to repair common issues will save you money, time, and stress. Plus, a well-maintained jack ensures a safe and efficient lifting experience. Whether you are a seasoned mechanic or a DIY enthusiast, understanding the ins and outs of 3 ton hydraulic floor jack repair empowers you to handle any lifting task with confidence.

:max_bytes(150000):strip_icc()/OrangeGloEverydayHardwoodFloorCleaner22oz-5a95a4dd04d1cf0037cbd59c.jpeg?w=740&resize=740,414&ssl=1)